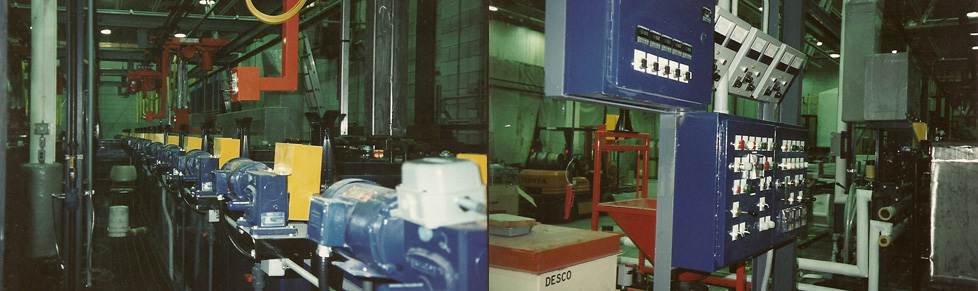

Holody Electro-Plating Limited offers both rack and barrel plating finishes whereby alkali cleaners remove oils & soils, and hydrochloric acid pickles the surface to remove oxides and etches the surface for plating.

Electroplating involves a power source (electricity), a plating solution that acts as an electrolyte, an anode usually consisting of the metal being deposited, and a substrate (part

being plated) which serves as a cathode. As a controlled (DC) current is passed from anode to cathode, the metal ions of the electrolyte are attracted and bind to the cathode (work piece) to form a cosmetic and protective film.

Plating Finishes

Finishes include Zinc, as well as a variety of post plating treatments which can be applied to the final product.

Plating thickness ranges from commercial thickness of 0.0001 (2.5um) for appearance and shelf storage life, to specification deposits up to 0.0008 (20um) for extended corrosion protection. Surface treatments which allow for extended corrosion resistance, colour identification, enhanced lubricity, and stress relief (baking) in ovens with open perforated baskets to eliminate hydrogen embrittlement within many hardened steels are readily available upon request.

Our finishes may be certified, upon request, to many automotive, military, nuclear, electrical, plumbing, appliance, commercial, and ASTM specifications.

Shipping & Delivery

Understanding that customer service and quick turnaround is essential for our customers to meet their commitments, our trucking fleet provides prompt pick up and delivery with less than 48 hour turnaround time on orders.

Regardless of the size of your order, Holody Electro-Plating Limited has the ability to service your needs with quality, service, price, and over 65 years of reputable industry experience.

Zinc Plating

Zinc Plating One of our Trucks

One of our Trucks